Guns, Uncategorized

ILWT’s “Drop-In” Scorpion EVO 9mm Custom 3-Lug Barrel

March 05, 2017

ILWT’s “Drop-In” Scorpion EVO 9mm Custom 3-Lug Barrel

ILWT’s “Drop-In” Scorpion EVO 9mm Custom 3-Lug Barrel, for Pistol or Registered-SBR (NFA) applications.

When the CZ SCORPION EVO was introduced in 2014 and then quickly followed by Colion Noir’s video-review, everyone took notice, and (im)patiently waited for it to hit the shelves. The sticker shock was low, and the lines of the gun looked impressive. Everyone wanted to feel it in their own hands.

Colion’s positive video review did not help one to remain patient to get a hold of the new EVO.

The first batch of guns showed up, and quickly sold out, leaving many wishing they had anticipated the guns’ selling-power and hit the ‘BUY’ button quicker.

More waiting, and an exercise in patience for many future buyers.

That seems like ages ago, and maybe it is, but the guns are now dispersed, plentiful and readily available.

With it’s popularity and potential, of course aftermarket has slowly and steadily been coming out with wonderful accessories and upgrades to transform the EVO into something can take on the HK MP5 and it’s clones.

The CZ Scorpion EVO is available in a 16″ Carbine model and also a Pistol version, most of which will wind up SBR’d (Registered under NFA) using CZ’s 922r Butt-stock assembly kit.

SBR’ing the scorpion is only the first step in the end-user’s tool-box to massage this gun into greatness.

Next a suppressor, picking a custom trigger-pack, sights & optics and whatever else one desires. Many companies are currently offering high-quality options for all of the above.

But what about improved accuracy? What about improved suppressor interfaces?

Enter In-Lead-We-Trust’s Custom barrel, for SBR’s and Pistol EVO versions.

Manufactured from imported German steel, button rifled at 1-10, with Proprietary chamber dimensions.

Much care was taken when squaring the chamber-bed into the center parallax of the bore, and also the lead in to the initial rifling shoulders.

ILWT test barrel: 9,000 rds fired various ammo types, zero malfunctions

Once the improved accuracy and reliability was there, the next step was interfacing the popular quick-release HK-type 3-lug attachment directly into the barrel itself. Reverse engineered from a German MP5, the 3-lug mount holds a perfect exterior/OD tolerance of 0.0005″. Perfect!

Not to leave out the suppressor owners using the standard 1/2-28 threads, those were also incorporated into the ILWT barrel.

ILWT went with a barrel interfaced 3-lug to increase the amount of rifling to it’s max for ballistics, vs a hollow-type 3-lug screw-on type adapter.

As with all of ILWT’s custom barrels, all critical suppressor attachment dimensions (3-Lug and single-point 1/2-28tpi) are fully concentric, and done on CNC state-of-the-art production-equipment.

The 1/2-28 threads are covered by ILWT’s proprietary thread protector (TP).

The TP does just as the name implies, protects the precision muzzle threads on the barrel.

Where the ILWT TP really shines in it’s design, is when using a 3-Lug suppressor.

Most 3-lug barrels do not have muzzle threads. When they do have both the 3-Lug and the 1/2-28tpi they are considered the “NAVY” variation.

When using the Navy variants w/ a suppressor, the TP is normally smaller in it’s outer-diameter (OD), and normally uses knurling for finger tightening. Which means you are losing the forward shoulder of the barrel/TP for stabilizing/aligning the suppressor.

The ILWT Thread Protectors are specifically designed to eliminate this, and stabilize the suppressor, eliminating any chance of a baffle strike when using a tight precision-tolerance baffle-stack.

The ILWT TP is concentric OD/ID and the outer diameter perfectly matches the OD of the shoulder area on the 3-Lug. Rearward of the front portion, the OD is stepped down in width, and horizontal serrations are added for finger grip when installing/removing. The smaller OD in the serrated area means the sharp-edges of the serrations (or normally knurling) will not make contact with the internal-surface of the 3-Lug suppressor’s attachment contact surface.

What does all this mean? It means you can have the stability of a non-threaded 3-Lug mount, but still enjoy the versatility of the 1/2-28 threads. You regain the stability through the Thread Protector’s perfectly spec’d front-shoulder OD.

You will also not be touching the Suppressors 3-Lug internal surfaces with sharp knurling.

Normally one loses stability when using a Navy design 3-Lug, but not so whit the ILWT Navy. The ILWT Navy TP ensures you have the same stability as a non-Navy (non muzzle threaded) HK 3-Lug.

Something Gained (1/2-28 muzzle), and Nothing lost (Stability). Perfect.

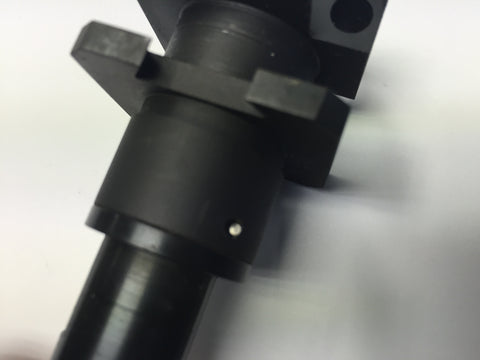

The ILWT Trunnion’s OD has been beefed-up around it’s threaded portion, and the use of a single pin had been employed.

The pin allows easy separation of the barrel from the trunnion, if needed, vs the multiple Stakings used by CZ OEM/Factory . The pin not only allows easier removal, but damage free removal, since the 5-6 stakings do not have to be ‘ground/machined’ off. Reassembly is that much easier as well, with the ‘pin’ design.

ILWT’s Beefed-up and ‘Pinned’ Trunnion

Moving on to the technical:

The barrel is made from 4140 steel, precisely lathed on state of the art Production-CNC equipment by highly trained professional technicians.

The trunnions are machined out of Ordnance steel, the extractor-relief machined, and then matched/timed to an individual barrel, when the barrel’s relief cut is made.

Extractor Relief cuts in the trunnion & matched barrel

Both the barrel and trunnion are serial numbered to ensure a correct ‘timing’ marriage throughout the rest of the production processes.

The two are then separated for a while, but will wind up back together at the end of the processes.

Serial numbered trunnion, for correct matching of clocked barrel

The barrels are melonited, which heat treats the metal 0.008″ deep and impregnates the surface with a very corrosion resistant & durable black Nitride finish.

Meloniting does not add material to the surfaces, so the dimensions of the parts remain perfectly within specification.

The trunnions head to the heat-treating portion of the process, to ensure they are brutally strong, yet still remain impact-resilient from impact from the weapon’s bolt during firing.

When both the barrels and trunnions are finished, they are sorted for serial numbers, so each barrel has the correctly timed trunnion reinstalled.

Once correctly torqued into the trunnion, both pieces are single-pinned in place, to ensure the barrel is positively held/clocked in it’s proper position.

After final assembly

In summary:

The highest quality materials, built on the highest quality CNC’s, and held to perfect specifications.

Proprietary chamber dimensions for improved accuracy and excellent reliability.

Both threaded muzzle and beautiful/spec’d 3-Lug interfaced into the barrel itself, for perfect concentricity, and longer barrel rifling, for increased velocity.

Thread protector with concentric shoulder for stabilizing 3-Lug suppressors.

Fluted barrel.

Finished in Hard melonite (Nitride) for hardness, wear and corrosion resistance.

Pinned bbl/trunnion for easier and damage-free removal, if needed.

Wrench flats on barrel.

Custom hand-guard collar & spacer included.

And lastly, the barrel assembly is ready and easy to “Drop in” to your CZ Scorpion Evo.

Recent Comments